OR - Fixing our Electrical System

Since we have owned Eximius, we have installed quite a few upgrades and my guess is that we're not the first to upgrade the boat and certainly not the first to make changes to the Electrical System. Every time I open an electrical panel I repeat - I'll have to fix that one day. Well that day is nearly here.

Where we started

We have installed or upgraded the following parts of the Electrical System

And all of that during the past 5 years of ownership. (or should that be 'ownerboat' ?)

During that time the state of the electrical system has improved simply because I have endeavoured to do the right thing and replace any wires where it was necessary and it was in most cases.

Now that we are aware of the kind of issues involved such as:- Incorrect Wire sizes, unnecessary butt joints in the wires, incorrect wire colors, inappropriate wiring terminals and buss bars and missing fuses (by missing I mean there are some systems that should be fused and they are not)

|

Example of poor wiring (in the bathroomf)

|

Here's an example.

There are many similar situations on the boat where wires have been joined rather than use a continuous run, the joints are typically twisted, soldered and then wrapped in electrical tape.

Worse are the 110v AC system wires that are joined with Wire nuts used in homes.

There are multiple wires that have nothing connected, just wires dangling.

Tie Wraps are abundant and it's not unusual to have 20 or more tie wraps within a 3 foot loom. That would be ok if they were each functional and neither redundant nor unused.

|

The Main Electrical Control Panel (Before)

|

So many things wrong here.

No separation of AC and DC panels.

No protective cover of AC breakers.

Incorrect terminals on lots of wires.

Kinda labeled wires.

Wrong size wires in many cases.

The solution - at least - my solution.

So far, I have upgraded the wiring that supplies power or data to the device that has been upgraded. But that does not have the kind of impact that I'm looking for in order to sleep well at night.

The big question is, "Where do we start" and I say "we" because this really is a joint effort. Peggy has a pretty enquiring mind and is happy to ask why I'm doing something. Peggy was a Nurse for about 40 years, if you see the amount of technology that Critical Care and Cardiac Care Nurses have to deal with on a daily basis, it's pretty obvious why I explain why I'm doing something or what I intend to do.

If we were to buy another boat, then one thing I would inspect with a much more educated eye would be the Electrical System. Our Boat Surveyor never mentioned it other than noting something that was not working.

Ok, to the task - The Solution.

I posted a question on the C34 Forum and the Association Secretary suggested reviewing the Wiki Links - Wow, there are at least two great examples of what owners have done to solve this issue.

From the Wiki, I learned about a great idea of installing a breadboard at the back of the electrical panel area to mount the Terminal Blocks rather than having them float around behind the panel creating unreachable locations. That will simplify a lot, the board can be made to secure with just a couple of screws then removed, mount the terminal blocks and reinstall it.

Here's a pic showing the concept.

|

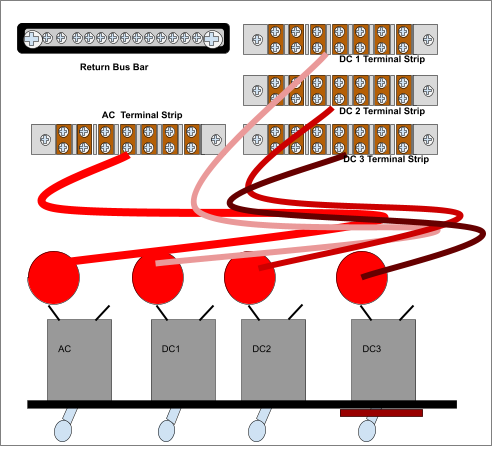

The General Concept of the Panel Upgrade

|

The idea is to have enough length of cable looms from the circuit breakers to the terminal blocks that the Breaker panel can be unscrewed from the framework and pulled away to provide access to the wiring terminals as well as make it easy to access the back of the panel.

AC Terminal Blocks (3 - Hots, Neutrals, Grounds)

- Main AC Power & Reverse Polarity Switch power

- Reverse Polarity indicator lamp

- 110v Outlets Power

- Inverter/Charger Power

- Water Heater Power

- Air Conditioning Power

DC Fuse Block (for normally on services)

- Nav table Light

- Stereo Memory Power

- Weather Clock Power

- Dry Bilge Timer

DC +ve Busbar

- Power from Battery Selector Switch

- Power to DC 1 Circuit Breaker Busbar

- Power to DC 2 Circuit Breaker Busbar

- Power to DC 3 Circuit Breaker

- Power to DC Fuse Block

The existing wires mostly go directly to the Circuit Breakers, some have inline fuses. So there should be plenty of wire to cut off the terminals and then label and connect new terminals with heat shrink tubing to reduce corrosion penetrating into the wires.

|

Layout of the Terminal Block Bread Board

|

The -ve, return, busbar is located in the area above the control panel and only requires that the cables are re-terminated, labeled and routed appropriately. I'll still check them to their source device to ensure they are solid, ie. do not include multiple unnecessary but joints and the wires are the correct size and color. If they do not meet those specs they will be replaced.

The spreadsheet below has the terminations for each of the circuits. I'll update it on progress.

Ok, everything has arrived, even the 1/4" 12"x24" White Starboard. I'll measure the space for the breadboard again before cutting. Moving ahead with our Cabin upgrade at the same time, so progress will shift between the two and I'll report as we proceed.

See you on the water.