Google Maps

Ok, I'm a sucker for net tricks, and Google Maps has a very cool feature that allows Distance Measurement. When I mentioned this to a sailing buddy, he asked if I would write up the process. So here goes.

How far is it from Point A to Point B on the Ocean?

Step 1: Open Google Maps and zoom into the area of interest like this:

This pic shows the map of the Atlantic Coast with Boca Raton at the North and Port Everglades Zoomed to 2 Miles. It's clickable so that you can go to the Map if you have an active Internet Connection.

Step 2: Place a Mark on the Map

I'm going to measure the distance from Lake Boca to Hillsboro Inlet and then to Port Everglades.

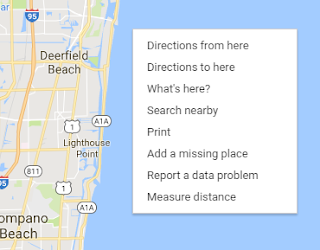

To place the 1st mark, right click on the Map close to the Inlet at Lake Boca, then select 'Measure Distance'

Now you should see the 1st Mark on the screen, (I have placed an arrow and text to point to the mark. It's that round black circle with a white core)

Now mouse down to the location where you wish the next mark, in my example, that's going to be the Hillsboro Inlet, Then Click and the distance from the 1st Mark to the Second will be shown.

In the current (February 2017) version of Maps.Google this line between the 1st Mark and the 2nd Mark has graduation marks along the line and the distance at the 2nd Mark

Step 4: Adding more Marks

When you click elsewhere on the Map, you'll see a new Mark with the distance shown to that Mark from the 1st Mark.

Now this is starting to become useful.

I can add marks between any other two marks just by dragging any point on the line between two marks.

To delete a mark, just click on the Mark and it's gone.

I use this process when I'm guestimating the distance for a Sailing trip. It's quick and easy.

I have not yet figured out how to share a Map including the Measured Distance Marks & Lines, so if you know how, please comment to share it.

The process is similar on a Tablet, but there's no Right Click Option,

On my Android Tablet, I follow the steps above, but to place the first mark I just touch and hold a point on the map, that plants a Marker and description a description at the bottom of the screen. If I tap that description, it brings up options including Measure Distance!

To add additional marks, scroll to where you want the next mark then just tap the + Add Point icon in the lower left corner of the screen. That same process can be repeated. The options on a PC are far better.

Just to prevent argument! I only use this process when I want to quickly measure distances. When it comes to Route Planning we use Garmin Home Port, that allows us to export our routes to our onboard GPS system.

I hope you found this useful. It's quick and dirty, but sometimes it's the quickest option that counts.

See you on the Water.

Paul

I have not yet figured out how to share a Map including the Measured Distance Marks & Lines, so if you know how, please comment to share it.

The process is similar on a Tablet, but there's no Right Click Option,

On my Android Tablet, I follow the steps above, but to place the first mark I just touch and hold a point on the map, that plants a Marker and description a description at the bottom of the screen. If I tap that description, it brings up options including Measure Distance!

To add additional marks, scroll to where you want the next mark then just tap the + Add Point icon in the lower left corner of the screen. That same process can be repeated. The options on a PC are far better.

Just to prevent argument! I only use this process when I want to quickly measure distances. When it comes to Route Planning we use Garmin Home Port, that allows us to export our routes to our onboard GPS system.

I hope you found this useful. It's quick and dirty, but sometimes it's the quickest option that counts.

See you on the Water.

Paul